The first question we must answer is, what are Kite boards made of? and how different construction materials affect the performance of the board?

Several years ago, boards made from foam were quite popular, and it remained that way for years. But the changing trends in the sport of kite surfing, with riders pushing new limits every day, required the manufacturers to look for more durable materials.

You see, most riders nowadays are more aggressive with their tricks with kite surfers who use twin tip boards jumping very high, landing hard and performing complex tricks with the tricks getting harder and more aggressive as years go by. As an added pressure, for the past 8 years many pros have started riding with boots. This adds extra strain on the kite board, and it actually hurts a bit their knees sometimes and their kite boards.

So why the shift to wood?

First let’s take a look at the weight comparison between the foam and wood:

Foam – 80 to 120 kilograms per cubic meter

EPS – Foam – 15 to 20 kilograms per cubic meter

Wood – 320 to 350 kilograms per cubic meter

We’re sure you noticed that using foam has a key advantage in terms of reducing weight as it is about 60% lighter than wood. Unfortunately the foam, it’s not pressure resistant. This is not an issue when used into the construction of the surf boards and windsurf boards as they are not subject to the same mount of pressure when jumping and because they are much thicker compared to kiteboards but for twin tip boards this can be a big problem.

As mentioned earlier, twin tip board riders tend to be more adventurous when it comes to doing their tricks and jumping high. Due to the extreme maneuvers that these riders perform, the weight and strain increases underneath the footpads or boots, which greatly affects the foam board as foam is prone to heel dents. After continuous exposure to the extreme pressure that comes with kitesurfers pushing boundaries with the sport, small blisters and pockets start to appear. A foam board cannot withstand hard jumps and radical riding as they wear out the structure of the board materials which will ultimately lead to a broken board.

There’s a remedy to this problem. Manufacturers have experimented with thicker lamination or by using modern materials like carbon, thick fiber glass or kevlar. The downside is, the main advantage of the foam (which is less weight) is lost.

Another method that manufacturers tried is the sandwich construction. However, it’s quite expensive to produce, so is not as widely used.

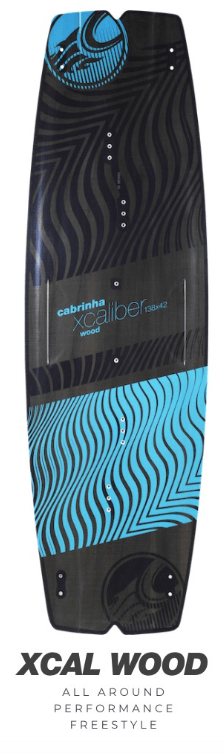

Wood Cores

Manufacturers found out that wood cores are a perfect fit for kite surfing twin tip boards. They are less prone to dents and more durable compared to foam. The wood also gives more pop in the waters which is what most twin tip riders prefer.

There are different types of wood that manufacturers use for twin tip boards. Some use Kopok wood for a core whilst others use the Paulownia wood core. Both kinds of wood come from fast-growing trees and they are a sustainable sources of wood; after all, we kitesurfers are lovers of the outdoors and would never want to use anything that negatively impacts our beautiful planet.

The wood core is then covered from top to bottom with fiberglass, basalt fiber, or a carbon fiber.

The carbon and fiberglass can be either in multi-directional or unidirectional. The unidirectional cloths structural elements are oriented in a single direction.

A lot of people ask it’s better fiberglass kite boards or carbon, now what you need to know is a lot of people want Carbon because carbon kite boards are lightweight! But don’t fall for that, it’s not a matter of the lightweight, carbon kite boards has a lot of energy retention and it does get released almost at 90% when you load up a carbon kite board it want to flex back and pop back on you while fiberglass kite boards has a way less energy response. so if you put them both together and you get a fiberglass sheet and you get a carbon sheet that is laid up and you flip them and load them up you will see the carbon will have a lot more loaders engine will come right back and pop a lot more energy in there that is the biggest difference of riding a carbon board or a glass board.

What are the benefits of carbon kite board and fiberglass kite board ?

The fiberglass allows the board to have a good flex and relatively low weight. That’s why it’s a popular choice for composite construction.

Premium boards use carbon fiber because of its low weight to strength ratio. It delivers a good pop in the waters for maximum performance.

Basalt fiber is the latest in the list of kite boarding materials. It is obtained from a melted volcanic rock which is converted into a fiber. It offers better flexibility and low weight which is ideal for twin tip boards.

A rail, which is made up of plastic material protects the board from impact. For finishing touches, a plastic top sheet is used to cover the entire board for added UV protection.

For sure another important difference is the price difference between carbon fiber kite boards and fiberglass kite boards

CONCLUSION

Manufacturers continuously develop new methods to process the materials. By doing this, the designers have more freedom to implement the exact board shape that they want. This will push the boundaries of design to make the board stronger and lighter to deliver a higher performance.

For more information about the different kite boards and the best board for your riding style you can visit our kite surf shop located at Nessnass Beach in Dubai or you can visit our online shop to check on our collection of kite surf boards available at our shop.